The Rise of DIY Welding: Why More People Are Picking Up the Torch in 2025

Introduction to Laser Cutting and Welding Machines

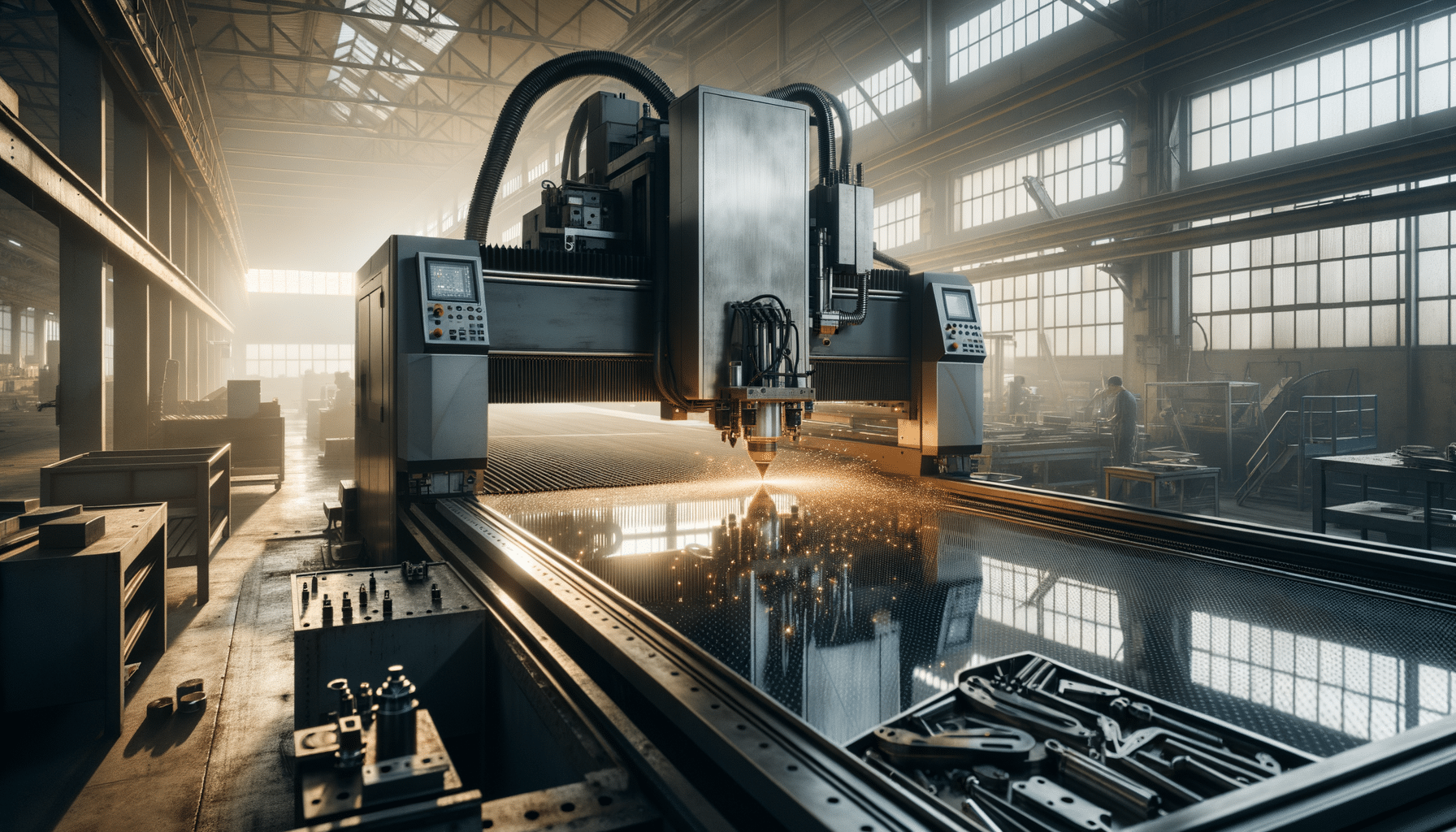

The industrial landscape has significantly evolved with the introduction of laser cutting and welding machines. These machines offer precision, efficiency, and versatility, making them indispensable in various sectors. The technology behind laser cutting involves using a laser to cut materials, while laser welding uses a laser beam to join materials. The precision and speed of these machines have made them a preferred choice in industries such as automotive, aerospace, and manufacturing.

Laser cutting and welding machines provide numerous advantages, including minimal material wastage, high-quality finishes, and the ability to handle complex designs. As industries continue to demand higher precision and efficiency, the adoption of these machines is on the rise. With advancements in technology, these machines are becoming more accessible to small and medium enterprises, further driving their popularity.

Exploring Laser Welding Equipment for Sale

The market for laser welding equipment is expanding, with a wide range of options available for businesses and individuals alike. As companies look to upgrade their production capabilities, purchasing laser welding equipment for sale becomes an attractive option. These machines are designed to provide exceptional welding quality, with features that enhance productivity and precision.

When considering laser welding equipment, it is essential to evaluate factors such as the type of materials to be welded, the thickness of the materials, and the desired finish quality. Additionally, the equipment’s power output, ease of use, and maintenance requirements are crucial considerations. By understanding these factors, businesses can make informed decisions when investing in laser welding equipment.

As the demand for laser welding equipment grows, manufacturers are offering innovative solutions that cater to various industry needs. From compact models suitable for small workshops to large-scale machines for industrial applications, the options are diverse. This variety ensures that there is suitable equipment available for every requirement, allowing businesses to enhance their production processes efficiently.

The Essential Welding Tools and Equipment

Welding is a fundamental process in manufacturing and construction, requiring a range of tools and equipment to perform effectively. Essential welding tools include welding machines, protective gear, and accessories that ensure safety and precision. Each tool plays a critical role in achieving high-quality welds and maintaining a safe working environment.

Key welding equipment includes:

- Welding Machines: These come in various types, such as MIG, TIG, and stick welders, each suited for different applications and materials.

- Protective Gear: Helmets, gloves, and aprons are essential to protect against sparks, heat, and UV radiation.

- Accessories: Clamps, wire brushes, and chipping hammers are crucial for preparing and finishing welds.

Investing in quality welding tools and equipment is vital for achieving reliable and consistent results. Proper maintenance and regular inspections are also necessary to ensure the longevity and performance of the equipment. As technology advances, new tools and innovations continue to enhance the welding process, making it more efficient and accessible to various industries.

Comparing Traditional and Laser Welding Techniques

Welding techniques have evolved over the years, with traditional methods still widely used alongside modern laser welding. Understanding the differences between these techniques can help businesses choose the right approach for their specific needs. Traditional welding methods, such as arc welding, rely on electrical currents to generate heat and join metals. These methods are well-suited for a variety of applications and are often more cost-effective for smaller projects.

Laser welding, on the other hand, offers a higher level of precision and speed. The focused laser beam provides deep penetration with minimal distortion, making it ideal for intricate and high-precision work. This technique is particularly beneficial for industries requiring detailed and precise welds, such as electronics and medical device manufacturing.

While laser welding equipment may require a higher initial investment, the long-term benefits often outweigh the costs. The choice between traditional and laser welding depends on factors such as project requirements, budget, and desired quality. By weighing these considerations, businesses can select the most suitable welding technique for their operations.

Conclusion: Embracing the Future of Welding

The welding industry is undergoing a transformation as more businesses and individuals embrace advanced technologies like laser cutting and welding machines. These innovations offer significant advantages in terms of precision, efficiency, and versatility. As the demand for high-quality welds continues to grow, the adoption of laser welding equipment is expected to rise.

For those interested in entering the welding field or upgrading their existing equipment, exploring laser welding equipment for sale presents an opportunity to enhance capabilities and stay competitive. By understanding the available options and making informed decisions, businesses can leverage these advancements to improve their production processes and achieve exceptional results.

As we look to the future, the continued development and accessibility of welding technologies will play a crucial role in shaping industries and driving innovation. Embracing these changes will ensure that businesses remain at the forefront of the welding revolution, ready to meet the challenges and opportunities of tomorrow.